Menu

-

-

F.A.Q

- How to identify genuine agarwood chip, natural or cultivated

- How to identify oil injection / absorption fake agarwood beads

- How to know if there are more than one oil in your oil

- How to make your wood bracelet or mala darker

- How to tell if an Agarwood bead sinks WITHOUT sinking it under water?

- How does back flow incense work and how do you burn it?

- Where to start if you don't know what agarwood is ?

- Why are you losing money if you buy seeds and plants?

- Which agarwood incense should I choose?

- Frequently Asked Questions

- Agarwood Related Articles

- Shipping

-

SHOP - Agarwood

-

SHOP - Other Fragrant Wood

-

SHOP - Incense Holder and Burner

-

- FREE guide book

- Testimonials

- "Why did you buy this?"

- Contact us

- About Us

- +61430284329

- Login

-

English

Why does your backflow cone incense smell bad?

May 03, 2024 8 min read

Part 1: How does backflow incense work, and how do you burn it?

Is it true that backflow cone incense smells bad?

A forum member who has been using incense for several years recently shared their unfortunate experience with backflow incense. Intrigued by the visually striking effect of these incense cones, which are often showcased in videos and photos featuring incense burners with smoke cascading downwards like a waterfall, the member decided to try them out.

However, the member found very little information about the fragrance of the incense itself; most reviews focused solely on the visual spectacle. Consequently, they purchased a burner that included some incense cones and two additional varieties to test.

After trying each type, the member reported that the primary appeal of this incense is visual. While the smoke descending the burner is mesmerising, the incense scent is extremely unpleasant. It appears that the ingredients used to make the smoke denser also impart a harsh, acrid odour. The actual fragrance advertised on the packaging is barely detectable in the smoke.

Post-burning, the residual odour resembled that of a campfire polluted with trash. It was so persistent that the member had to burn two sticks of traditional Indian incense to mitigate the smell. Additionally, the ceramic burners absorb the unpleasant oil from the cones, requiring thorough cleaning to remove it. If transferred to the hands, this oil clings stubbornly, resisting numerous washes.

The member advises against spending money on these products, stating that their experience was so disappointing that they felt compelled to share it.

I agree with him because just like him, I bought some colourful backflow incenses in the market places. Some of them are really bad.

Reason backflow incense smells bad

Burnt notes due to overheating. So What causes overheating?

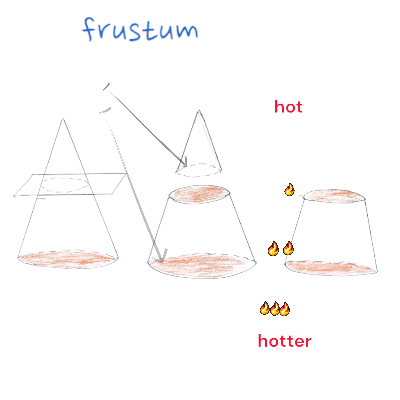

Shape and Heat Distribution:

The structure of a backflow incense cone is designed in such a way that it is narrower at the top and wider at the bottom. This design influences how the cone burns. At the narrow top, the heat generated during burning is relatively small, which means the materials burn at a lower temperature and produce milder scents.

Consider the above

The base of the cone has the largest diameter. The larger the base, the more energy it as, the larger amount of material burnt, the hotter they are.

As the cone widens towards the bottom, it allows more material to burn at once. This increases the heat output significantly. The high heat at the broader base of the cone causes the materials to burn more intensely, which can result in the production of harsher, stronger, and sometimes less pleasant burn notes. The intense heat can alter the chemical composition of the incense, leading to a less desirable aroma, particularly if the incense is not consistently attended to or if the airflow affects how the incense burns unevenly.

Quality of Ingredients:

The quality of the ingredients used in making backflow incense cones is crucial to the resulting smell. High-quality ingredients tend to produce pleasant, clean, and clear scents. Conversely, if the incense is made with inferior or inappropriate materials, the smell can be unpleasant. Bad ingredients may include low-grade resins, essential oils, and other additives that do not burn cleanly or that produce offensive odors when heated. Moreover, the use of synthetic fragrances or fillers that do not handle high heat well can exacerbate bad smells.

Poorly chosen or processed ingredients might release unpleasant volatile organic compounds when subjected to the intense heat at the bottom of the cone, leading to an overall negative sensory experience.

The sticky, gluey substance you find at the bottom of the ash after burning an incense cone is typically composed of the binders or adhesives used to hold the incense materials together. In incense cones, binders are crucial for maintaining the cone's shape and ensuring that it burns properly. Common binders include natural gums like gum arabic, tragacanth, or makko powder (a type of bark powder from the tabu-no-ki tree), which are substances that can leave a residue when burned.

As the incense burns, most of the aromatic materials are vaporised or turned into ash. Still, some of the compounds or the binders may not completely combust, especially if the burning temperature is not high enough. This incomplete combustion results in the sticky residue you observe. This is normal and varies depending on the specific formulation of the incense cone.

Overall, the unpleasant smell from backflow incense could be a combination of inefficient burning dynamics due to the cone's shape and the use of low-quality or unsuitable ingredients. Ensuring even heat distribution and using high-quality, natural ingredients can help produce a more pleasant fragrance from backflow incense cones.

Now that you know why backflow cone incense smells bad, let’s make it smell good. I will show you how.

How to make backflow cone incense smell good

The main reason you use backfow incense is mesmerising visuals. You cannot stop looking at it. The backflow smoke from the cone makes it look like clouds floating around the mountain.

So can you have the visual effect as well as the aromatic experience?

Yes you can

The most important thing is the ingredients. You cannot have good incense with bad ingredients. For example, rotten apples no matter what you do with it, do not taste as good as fresh apple.

First you need good ingredients. For example, if you like cinnamon incense, you make incense with cinamon from cinamon bark. Or if you like sandalwood, you can make incense with sandalwood powder. Not synthetic ingredients.

I will be biased here. As my brother is an experienced agarwood grower so I have been using Agarwood for a while.

I also use sandalwood and cedarwood to make my incense

I wish you can smell the aroma of these three powders I have here right now. You cannot make “bad” incense with these wonder wood powders.

Next, the structure of the cone

The narrower the base, the better the smell. That is why people who do not care about the backflow prefer the stick incense. As a cylinder shape, the diameter is the same from the top to the bottom, it means the temperature varies little.

In the case of cone, the frustum is different, smallest in the top and largest in the bottom. The closer the flame to the bottom, the hotter it is as there are more material to burn

A new way to burn frankincense

You probably know frankincense and myrrh. Usually, you use charcoal to heat them.

To achieve the optimum burn, we usually wait for the charcoal to form the ash layer. Then, you place them on top and you smell the sweet balsamic woody, earthy, and slightly spicy with a hint of citrus.

Tree resins like frankincense and myrrh are difficult to pulverise into incense. Many incense makers attempt, but the result is uncertain. During the burn, the resin melts, which may “extinguish” the fire, so incense makers usually use them in liquid form—i.e., essential oils or fragrant oils. The experience of burning frankincense essential oils differs greatly from its solid forms.

So if you want to smell frankincense in an incense all you need to do is to place the frankincense tear on top.

As the cone burns from the top, it forms a soft, white ash layer. Once the backflow cone has formed a sufficient layer of ash and the larger part of the cone is actively burning, take a small piece of frankincense resin and place it gently on the ash-covered top. Frankincense, known for its sweet, woody aroma, will slowly start to melt and burn due to the heat from the incense cone beneath.

Enjoying the Experience: As the incense burns, each element releases its unique fragrance, mingling in the air to create a layered, multi-dimensional aroma. This not only pleases the senses but also helps in relaxation and meditation, making it an ideal setting for contemplation or simply enjoying a peaceful moment.

Visual and Aromatic Appeal: The visual aspect of the smoke flowing downward, combined with the ascending fragrances, creates a holistic experience. This spectacle is not only a treat to the eyes but also a feast for the olfactory senses.

So, how to make a small batch of backflow incense

Ingredients and Materials:

The below is not a strict guideline, it is my experience only. Other people have different ways, there is no right or wrong answer here.

- Ingredients: 9 grams (can be any ratio as long as the total is 9 grams approximately: you can include but not limit to cinnamon, agarwood, sandalwood, or cedarwood)

- Adhesive Powder (Scent Binder): 1 grams of Litsea Glutinosa powder

- Mixing Bowl

- Optional: Backflow Incense Cone Molds, if you do not have it, you can simply use hand like how you play with clay.

- Water (as needed)

Instructions:

Step 1: Prepare the Incense Dough

- Grind the Wood if you do not have fine powder wood incense. The finer the powder, the more uniform the burn will be.

- Mix with natural Adhesive Powder: Transfer the ground ingredients into a mixing bowl and add 1 gram of Litsea Glutinosa powder. This natural adhesive will help bind the mixture together and ensure that your cones hold their shape while burning.

- Add Water: Slowly add small amounts of water to the mixture while stirring continuously with a spoon or spatula. Add just enough water to form a dough-like consistency that is malleable but not too wet.

Step 2: Make the Cones

- If you have a backflow mold then you can insert the mixture into your backflow incense cone mold and make sure it is clean and dry. If you don’t, you can use your hand to make cone shaped incenses.

- Shape the Dough: Pinch a small amount of the incense dough and press it firmly into the mold. Make sure to compact the dough well to avoid any air pockets, which can affect how the incense burns.

- Create a Hole for Backflow: Use a small rod or stick to create a hole running through the center of the cone from the bottom to the top. This hole is crucial as it allows the smoke to flow downward in the characteristic backflow pattern.

Step 3: Dry the Cones

- Remove from Mold: Carefully remove the shaped cones from the mold and place them on a drying rack.

- Air Dry: Allow the cones to air dry in a cool, dry place away from direct sunlight for at least 24 to 48 hours. The drying time can vary depending on the humidity and temperature.

It does not have to be pretty to use. So when your cone incenses are dried, it can look "weird", especially if you do not use a mold to make the cones.

Step 4: Start burning

Light the tip of the cone, allow it to burn for a few seconds, then blow out the flame. The cone should begin to smoulder, causing the smoke to drift down through the centre hole, creating a mesmerising backflow effect. After a few minutes, use incense tweezers to place the frankincense on top as desired, and enjoy the rich, aromatic blend of natural woods and resin. Be cautious and avoid any direct contact with flame.

As frankincense is hard to grind, this method allows you to enjoy its aroma without the need for pulverising.

Final Step: Enjoy Your Incense

Creating backflow incense cones at home can be a deeply satisfying craft. It offers both a creative outlet and a way to personalize your home's aroma.

Leave a comment

Comments will be approved before showing up.

Also in News

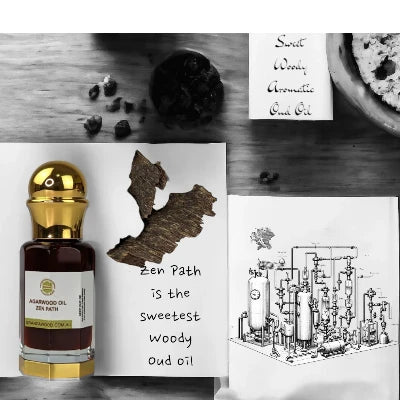

Anoint with The Zen Path, and you will never yearn for the artificiality that numbs the senses

March 03, 2024 2 min read

You say: “Your Agarwood is too expensive”. Let’s Reason Together - about Price

February 14, 2024 8 min read